How to Measure Bolt Pattern for Accurate Wheel Fitment in 2025

Understanding how to measure bolt pattern is essential for any vehicle owner or automotive enthusiast considering wheel upgrades. Knowing the correct bolt pattern of your vehicle ensures that you achieve optimal wheel fitment and compatibility. In this guide, we will delve into the intricacies of bolt pattern measurement, from basic definitions to actionable steps for accurate measurement.

Understanding the Basics of Bolt Pattern Measurement

Before diving into the specifics of measuring bolt patterns, it’s vital to understand what a bolt pattern is. In automotive terms, the **bolt pattern** refers to the arrangement of bolts used to attach a wheel to a vehicle’s hub. This configuration significantly affects wheel fitment and overall vehicle performance. The most common terminology includes the **bolt circle diameter** (BCD) and the number of bolt holes, which together form the bolt pattern, expressed as ‘X Y’ where X is the number of bolts and Y is the BCD measured in millimeters or inches.

What is Bolt Circle Diameter?

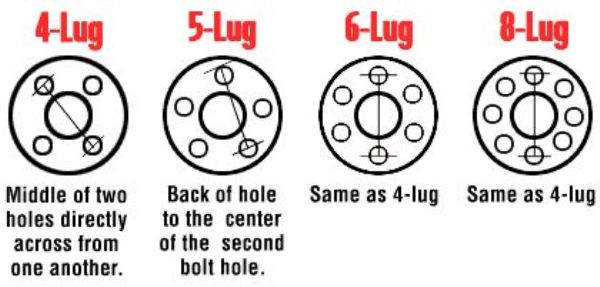

The **bolt circle diameter** is a crucial component of the **bolt pattern measurement**. It is the diameter of an imaginary circle that passes through the center of each bolt hole on the wheel hub. To measure the BCD accurately, you can use a measuring tape or caliper. For wheels with an even number of bolts, measure from the center of one bolt hole to the center of the directly opposite hole. For wheels with an odd number of holes, measure from the center of one bolt hole to the center of the other adjacent bolt hole and multiply that by 1.414 (the square root of 2). This method ensures an **accurate bolt pattern measurement** for optimal fitment.

Measuring Bolt Hole Spacing

In addition to determining the bolt circle diameter, it’s important to understand the **bolt hole spacing**. This refers to the distances between individual bolt holes, a factor critical for ensuring that wheels fit properly on the hub. Miscalculating bolt hole spacing can lead to installation issues or, worse, unsafe driving conditions. Tools such as bolt pattern gauges or calipers are recommended for securing an accurate reading of the bolt hole spacing. Repeated measurements are advisable to ensure precision.

Step-by-Step Guide to Measuring Bolt Pattern

Having an accurate technique for measuring bolt patterns can save you time and effort when selecting new wheels or tires. Below is a detailed **step-by-step bolt pattern measurement** guide to help you through the process.

Gather Necessary Tools

Before you begin measuring, ensure you have the right tools. A measuring tape, caliper, and a **bolt pattern tool** are essential for effective measurement. Each tool serves a specific purpose, such as providing precise measurements for **bolt pattern variations**. Always double-check your tools for calibration to ensure confidence in your results.

Measuring Process Example

The following example outlines the measuring process for a vehicle with a common bolt pattern: a 5-lug wheel arrangement.

- Begin by lifting the vehicle safely using jacks.

- Remove the wheel to access the hub.

- Use a caliper to measure the center-to-center distance between one bolt hole and the next adjacent hole. For a 5-lug pattern, repeat this process for the next hole. The calculation will use this distance.

- If measuring a 4-lug wheel, measure bolt holes diagonally. Confirm by measuring from a bolt hole to the one opposite it.

After completing your measurements, you can compare the findings with a **bolt pattern guide** specific to your wheel type to determine compatibility.

Common Bolt Patterns and Their Significance

Understanding common bolt patterns is vital when seeking replacements or upgrades. The significance of proper bolt pattern measurement extends to vehicle safety and performance. Below are a few standard bolt patterns:

Popular Bolt Patterns for Cars and Trucks

For cars, some of the most **common bolt patterns** include 4×100, 5×114.3, and 5×120, while trucks frequently utilize 6×139.7 or 8×165.1. Identifying your vehicle’s bolt pattern is crucial before purchasing new wheels or rims. Most vehicles provide this information in their specifications; however, verifying through measurement is always advisable to avoid fitting complications.

Using a Bolt Pattern Calculator

A **bolt pattern calculator** can also streamline your measurement process. These calculators allow you to input your measurements, which can help you identify standard and alternative fitments. Such tools are particularly beneficial for those less familiar with **automotive terminology** or seeking fast verification. However, ensure you validate the information consistently.

Importance of Ensuring Correct Bolt Pattern

Ensuring the correct bolt pattern is crucial, as mismatched patterns can lead to dangerous driving conditions and damaging your vehicle’s structure. Proper measurement not only enhances driving stability but also improves handling. Various bolt pattern sizes cater to a lack of standardization within the automotive industry, making precision indispensable.

Consequences of Incorrect Bolt Pattern Measurements

Mismatched bolt patterns can result in numerous complications, ranging from poor handling to failure of lug nuts. An irregular or irregularly tightened lug nut can lead to wheel detachment, potentially causing severe accidents. Thus, understanding **the relevance of bolt pattern measurement** cannot be overstated; it’s a matter of both performance and safety.

Examples and Comparisons of Bolt Patterns

Using examples of different vehicles can help illustrate the differences in bolt patterns and provide insights into measuring techniques. For instance, the Ford F-150 utilizes a 6×135 bolt pattern, while Honda Civics generally feature a 5×114.3 pattern. By comparing these specifications, you can better appreciate the diversity and requirements involved in **measuring wheel bolt patterns** correctly. Always cross-reference with manufacturer specifications.

Key Takeaways

- Accurate **measurement of bolt patterns** is vital for vehicle compatibility.

- Tools like calipers and bolt pattern gauges are effective for precise measurements.

- Familiarizing yourself with common bolt patterns helps streamline the fitting process.

- Avoid mismatched patterns as this can significantly impact vehicle safety and performance.

- Leveraging bolt pattern calculators can expedite your measurement and comparison process.

FAQ

1. How can I determine my vehicle’s bolt pattern if I don’t have the specifications?

If the vehicle specifications aren’t available, you can measure the bolt pattern yourself using a caliper. Access the wheel hub, measure the center-to-center distance of selected holes, and use these findings to compare them against common patterns. If you’re unsure, referring to a **bolt pattern guide** or consulting automotive forums can be helpful.

2. Are there tools specifically designed for measuring bolt patterns?

Yes, there are several tools designed for this purpose, including **bolt pattern tools** specifically designed for ease of use. You can opt for measuring calipers, as well, which provide more versatile applications. Combine these tools with bolt pattern charts to enhance accuracy during the measurement process.

3. What should I do if my measured bolt pattern does not match standard sizes?

In situations where the measured bolt pattern does not match any standard sizes, you may be dealing with a custom or unique bolt pattern. This scenario often occurs with modifications or aftermarket wheels. Consult a professional or a trusted mechanic for advice on adapting or selecting the appropriate fittings.

4. Can aftermarket wheels have a different bolt pattern than OEM wheels?

Yes, aftermarket wheels frequently come with different bolt patterns compared to OEM wheels. It’s crucial to verify fitting compatibility through accurate measurements to ensure safety and performance. Always consult with a knowledgeable supplier or technician when considering aftermarket options to prevent mismatched patterns.

5. How can mismatched bolt patterns affect my driving experience?

Having a mismatched bolt pattern can weaken the connection between the wheel and the hub, potentially causing vibrations, steering issues, or, in severe cases, wheel detachment. This can lead to dangerous driving conditions, reduced speed stability, and an increased risk of accidents. Always ensure that the bolt patterns align perfectly for safety.

For additional resources on wheel fitment and bolt pattern specifications, check out these links: Comprehensive Wheel Fitment Guide, Understanding Vehicle Specifications.